Views: 0

In the holiday lighting market, the C9 bulb is an icon. However, not all bulbs are created equal. A high-quality commercial-grade C9 LED is the result of precision engineering, advanced materials science, and strict quality control.

Below, we take a look behind the scenes to see exactly how these durable bulbs are manufactured.

1. The Source: Precision SMD LED Chips

It all starts with the light source. Modern high-quality bulbs move away from older “dip” LEDs and utilize advanced Surface Mount Device (SMD) technology. The process begins with the growth and cutting of semiconductor wafers. Crucially, manufacturers perform a strict “binning” process. This sorts the chips by voltage, brightness, and color temperature to ensure that every bulb in a string matches perfectly, eliminating the “off-color” look found in cheaper alternatives.

2. Circuit Design: More Than Just Light

The selected LED chips are mounted onto a vertical PCB (Printed Circuit Board). Professional C9 bulbs integrate rectifiers and resistors directly onto this board. This internal circuitry is vital for regulating current, handling voltage fluctuations, and significantly reducing visible flicker. This engineering ensures the bulb lasts longer, even on unstable power grids.

3. Housing: The Strength of Polycarbonate

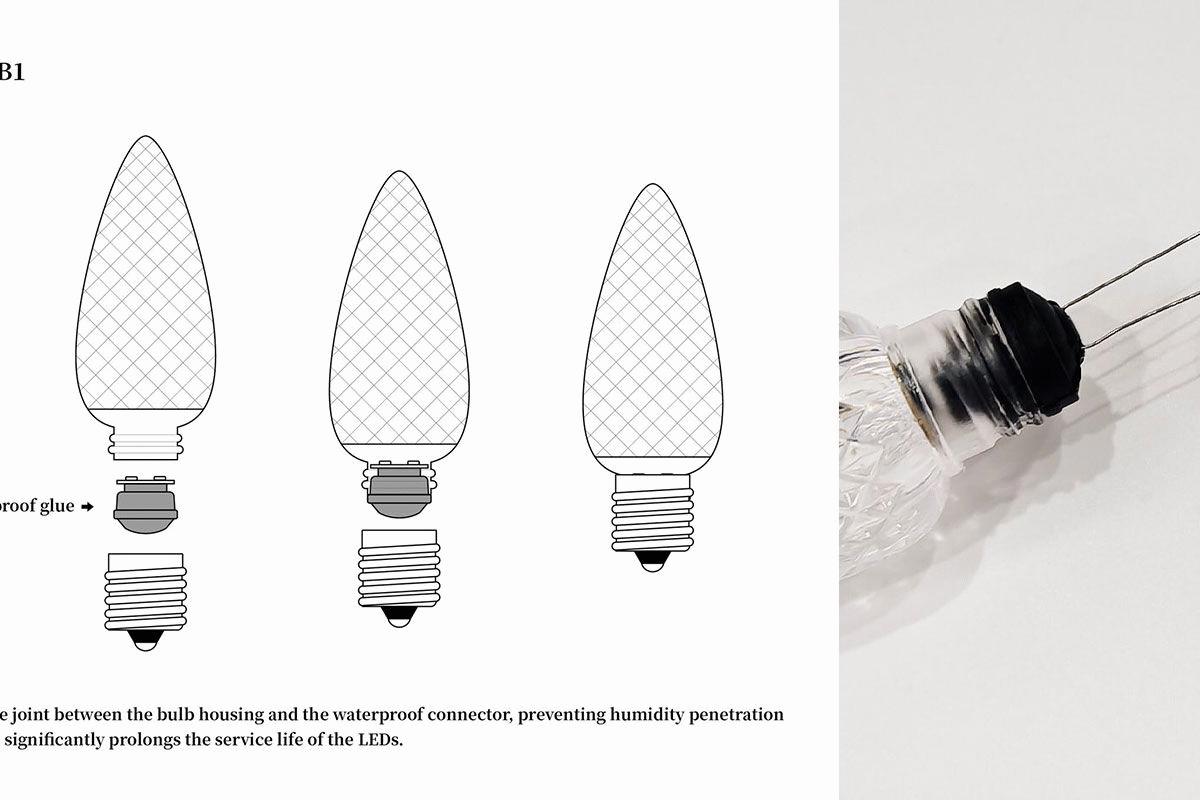

Once the circuit is ready, it needs protection. The bulb lens is injection-molded using Polycarbonate (PC) rather than glass or cheap plastic. Polycarbonate is virtually unbreakable and contains UV inhibitors to prevent the lens from turning yellow or brittle after years of sun exposure. Internally, the lens features a prismatic “diamond-cut” design. This diffuses the directional LED light, creating a warm, omnidirectional glow that mimics traditional incandescent bulbs.

4. Assembly & Sealing: Weatherproofing

Durability is determined here. The circuit board is inserted into a standard E17 intermediate base. To achieve a high waterproof rating (IP65+), the connection between the lens and the base is sealed using industrial-grade adhesives or ultrasonic welding. This airtight seal prevents rain, snow, and humidity from corroding the internal electronics.

5. Quality Control: The Burn-in Test

Before packaging, the finished bulbs undergo a rigorous “Burn-in Test.” They are powered on continuously for 24 to 48 hours to simulate extreme usage. This step identifies and weeds out any early failures. Only bulbs that maintain stable brightness and color throughout this test are approved for shipment.

Summary: From chip binning to ultrasonic sealing, every step of the manufacturing process is designed to solve the main problems of outdoor lighting: water ingress, breakage, and color inconsistency. Understanding these details helps ensure you are investing in a product built to last.