Views: 0

At Solunix Lite, we take pride in producing C9 LED bulbs that meet the highest standards of performance and reliability. Our manufacturing process is precise and efficient, ensuring every bulb delivers consistent brightness, durability, and safety. Below is a detailed look at each stage of our production.

Step 1: Install the LED Chip

The process begins by installing the LED chip into the bulb shell. This step forms the foundation of the bulb’s brightness and energy efficiency. After installation, the conductive wires are adjusted to ensure stable electrical flow.

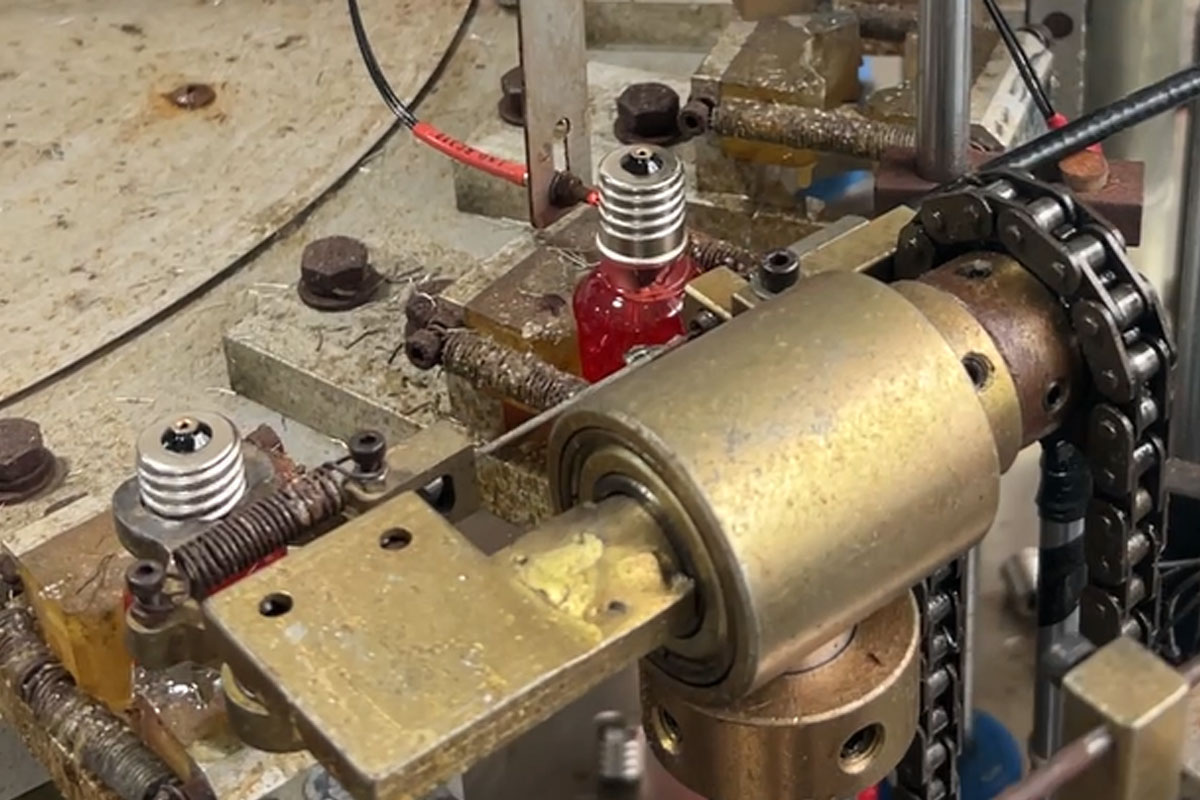

Step 2: Automated Production Line

Once the LED chips are installed, the bulbs enter an automated production line. Advanced machinery handles the remaining stages to maintain accuracy, consistency, and production efficiency.

Detailed Operations:

Step 3: Adjust LED Wire Spacing

The first automated task is to adjust the spacing between the LED wires. This ensures optimal current distribution, allowing the bulb to operate efficiently and reliably.

Step 4: Test LED Illumination

Next, we perform an initial light test to confirm that each LED chip lights up correctly. This guarantees that only functioning bulbs proceed to the next stages.

Step 5: Trim LED Wires

At this point, one of the LED wires is precisely trimmed to ensure proper electrical connectivity and maximize efficiency.

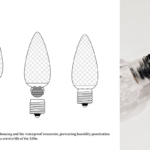

Step 6: Inject Waterproof Sealant

Using our patented waterproofing technology, we inject a specialized sealant into the bulb. This is crucial to protect against moisture and to ensure long-term outdoor durability.

Step 7: Press the Sealant Sleeve and Housing

After sealant injection, the sleeve is pressed tightly against the bulb housing to create a solid, moisture-proof seal that prevents contaminants from entering.

Step 8: Bend the Second LED Wire

The second LED wire is carefully bent and positioned to ensure that all electrical components remain secure and properly aligned inside the bulb.

Step 9: Align Sealant and Housing

We fine-tune the alignment between the sealant and outer shell, ensuring perfect sealing with no gaps or misalignments that could compromise quality.

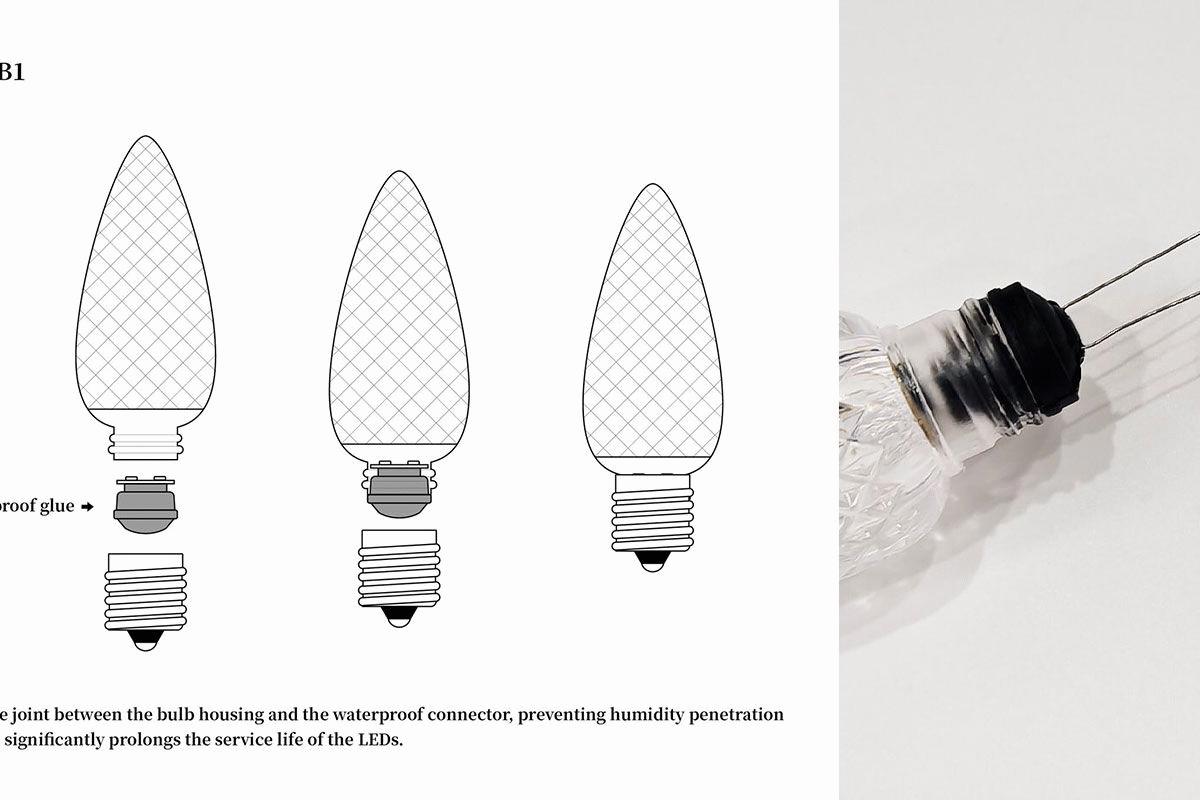

Step 10: Attach the E17 Screw Base

The standard E17 screw base is then installed, ensuring full compatibility with all common lighting sockets.

Step 11: Preliminary Tightening of the E17 Base

The E17 base is first hand-tightened to ensure a secure connection with the internal components.

Step 12: Final Tightening of the E17 Base

We then fully tighten the E17 base for maximum stability, preventing any electrical or structural issues during use.

Step 13: Lighting Test

Once fully assembled, each bulb undergoes a final lighting test to ensure it illuminates properly and passes all functionality checks.

Step 14: Trim Excess LED Wires

Any excess LED wire is carefully cut away, leaving a clean, professional finish that enhances both appearance and performance.

Step 15: Solder the Metal Contacts

The metal contacts at the bulb’s base are soldered to strengthen electrical connections, ensuring long-lasting safety and performance.

Step 16: Final Lighting Test

A second lighting test is performed to verify that the soldering process did not affect the bulb’s performance.

Step 17: 135V High-Voltage Aging Test

Each bulb is subjected to a 135V high-voltage impact aging test to ensure that it can withstand power fluctuations and extreme conditions.

Step 18: 120V Aging Test

Next, the bulbs go through a 120V long-duration aging test, simulating real-world operation to confirm stability and reliability over time.

Step 19: Automated Quality Screening

An automated testing system categorizes bulbs into “Qualified” and “Unqualified.” Only bulbs that meet all standards move forward.

Step 20: Final Manual Inspection

Our quality control team performs a detailed manual inspection to ensure every bulb meets Solunix Lite’s premium quality standards. Any product that fails this inspection is rejected.

Conclusion

From the precise installation of LED chips to the final inspection, every step in our C9 LED bulb production process is designed to guarantee top-tier quality.

For contractors and distributors, understanding our process means knowing the level of care and precision that goes into every bulb—ensuring that your customers receive products that are reliable, efficient, and built to last.